Canning Machine Leading Manufacturer

Canning Machine Manufacturer : Elevating the Standard with GX Canning

Elevate your production capabilities and efficiency as you scale your business with GX Canning’s automated craft canning equipment. As a premier canning machine manufacturer, we’re not just participating in the industry; we’re redefining it.

At GX Canning, we understand that a craft canning line is more than just a series of machines. It’s the heart of your beverage packaging operation, vital for encapsulating the essence of your craft beverages – be it cocktails, beer, ready-to-drink products, wine, ciders, kombucha, cold brew, seltzer, or carbonated drinks. Our canning lines are meticulously designed to include everything you need: from advanced depalletizers and efficient rinsing systems to precision filling and sealing mechanisms, complemented by seamless conveyors for smooth can transportation.

We pride ourselves on being the go-to canning machine manufacturer for those who demand nothing but the best. Our commitment to excellence and unparalleled customer care has positioned us as the #1 solution for canning high-quality products. Our canning lines, machines, and systems are not just built; they are crafted with precision and care, pushing the standards of the industry to new heights.

Our craft canning equipment will streamline your production

We believe in perfection. We didn’t just enter the canning machine market; we set out to perfect it. Every component of our canning lines reflects our dedication to quality and innovation. Join us in this journey of excellence and discover how our state-of-the-art canning solutions can transform your production process.

With GX Canning, you’re not just buying a machine; you’re investing in a future of unparalleled quality and efficiency. Discover our categories of equipment to improve your production.

Craft Canning Equipment

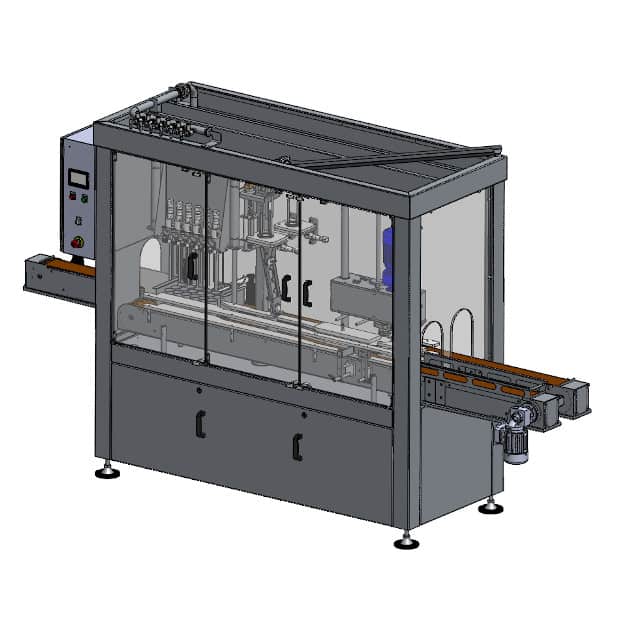

As a canning machine manufacturer, we design and built 100% of our high quality canning systems.

Let’s discover which canning machine fits your needs.

Bottling Equipment

Craft Food | Spirits | Sauce | Condiment | Syrup

Canning Equipment

Beer | RTD | Cocktails | Wine | Cider | Kombucha

About Us

Our mission is to help your business grow by providing quality products, reliable and durable automated craft canning machines. It is by putting forward our values of innovation, transparency, integrity and passion that we are committed to provide machinery at the cutting edge of technology. We pride ourselves on our values of innovation, transparency, integrity, and passion, and we’re committed to delivering cutting-edge technologies and application-specific packaging solutions for a diverse range of products.

Read some of our customer experience stories

At GX canning, we care about offering quality customer service and superior level product

What Is Your Next Craft Beverage Canning Project ? Let Us Know The Details And We’ll Get Back To You With A Proposal Built To Your Needs.

What is a canning machine?

A canning machine is a specialized piece of equipment used to fill and seal cans with various types of beverages. Canning machines come in a variety of sizes and types, ranging from small, manual models to large, fully automated systems capable of filling and sealing thousands of cans per hour.

Canning machines include several components, such as:

- A can depalletizer to unload empty cans;

- A conveyor system to move the cans from the depalletizer to the canning machine

- A twist rinse to flip the can, clean it and print a code on it

- A series of filling heads to fill the can and a seamer to seal the lid on the can

The filling machine injects the product into the can, while the can seamer secures the lid or end onto the can. Depending on the type of beverage being canned, the machine may also incorporate additional components such as a nitro doser to add a drop of nitrogen in the can before sealing the lid.

What are different types of canning machines?

- Rotary and linear models;

- Atmospheric and counter-pressure fillers;

- Seaming machines for lids or ends;

What is a depalletizer?

A depalletizer is a machine used to unload stacks of containers, such as bottles or cans, from pallets and place them onto a conveyor or other handling system. Depalletizers are commonly used in industries that handle large volumes of containers, such as the food and beverage industry.

GX Canning’s depalletizing systems include a motorized mechanism that moves the pallets into position and then push the empty cans on a conveyor to remove them from the pallet. The containers are then conveyed to the next stage of the production process, such as filling, labeling, or packaging.

What are different types of depalletizers?

There are several different types of depalletizers available, including low-level, high-level, and robotic models.

- Low-level depalletizers are designed to unload pallets at floor level;

- High-level depalletizers lift the pallets to a higher elevation before unloading;

- Robotic depalletizers use robotic arms to remove containers from pallets and can be programmed to handle a variety of container types and sizes.

What is the importance of a canning machine in the craft beverage industry?

In the craft beverage industry, the canning machine plays a pivotal role in ensuring product quality, freshness, and longevity. As the demand for craft beverages like beer, kombucha, wine, and cider grows, so does the need for efficient packaging solutions. A canning machine allows producers to seal their beverages in airtight containers, preserving the flavor and preventing contamination. Moreover, aluminum cans are lightweight, recyclable, and protect the contents from light and oxygen, both of which can degrade the quality of the beverage. Investing in a reliable canning machine ensures that craft beverage makers can meet consumer expectations for taste and quality, while also benefiting from the cost efficiencies and environmental advantages of canning.

How does a canning line enhance the efficiency of beverage production?

A canning line is a game-changer for beverage producers, especially in the craft sector. It streamlines the packaging process, ensuring that beverages are canned rapidly, consistently, and with minimal waste. For craft beverages like beer, kombucha, wine, and cider, maintaining the integrity of the product is paramount. A modern canning line ensures that each can is filled to the precise level, sealed perfectly, and undergoes rigorous quality checks. This not only reduces the chances of product spoilage but also ensures that consumers receive a consistent product every time. Additionally, automated canning lines can handle large volumes, allowing producers to scale up their operations and meet growing demand without compromising on quality. In essence, a canning line is an investment in efficiency, quality, and scalability for any beverage producer.

Why are more craft beverage producers transitioning to canning over traditional bottling methods?

The shift from bottles to cans in the craft beverage industry is driven by several compelling reasons. Firstly, cans offer superior protection against light and oxygen, both of which can adversely affect the taste and quality of beverages like beer, kombucha, wine, and cider. This ensures that the beverage inside remains fresh and true to its intended flavor profile. Secondly, cans are lightweight and compact, making them more cost-effective to transport and store. This translates to reduced shipping costs and a smaller carbon footprint. Additionally, cans are more environmentally friendly, being recyclable and often made from a high percentage of recycled material. The modern consumer is also increasingly on-the-go, and cans offer convenience with their portability. Lastly, the canning process, especially with advanced canning machines and canning lines, is faster and more efficient than bottling, allowing for higher production rates. All these factors combined make canning an attractive option for craft beverage producers looking to optimize their operations and cater to modern consumer preferences.

How does canning preserve the authentic flavors of craft beverages like beer, kombucha, wine, and cider?

Canning plays a crucial role in preserving the authentic flavors of craft beverages. Here’s how:

- Protection from Light: Light, especially UV rays, can cause certain compounds in beverages like beer to break down, leading to off-flavors often described as “skunky.” Aluminum cans block all light, ensuring the beverage inside remains unaffected.

- Airtight Seal: Oxygen is a major enemy of freshness in craft beverages. When exposed to oxygen, beverages can oxidize, leading to stale or cardboard-like flavors. Cans, when sealed using a quality canning machine, provide an airtight environment, preventing any oxygen ingress.

- Material Interaction: Unlike some plastic or glass containers, the inner lining of aluminum cans doesn’t interact with the beverage inside. This ensures that the drink’s flavor remains unaltered.

- Temperature Control: Cans chill faster than bottles. Rapid cooling helps lock in the beverage’s freshness and flavor, ensuring that consumers get the best tasting product when they crack open a can.

- Portability: The durability and compactness of cans mean they can be taken to places where glass bottles might be impractical or prohibited, like beaches or hiking trails. This ensures that the beverage can be enjoyed in its best state, fresh from a chilled can, in a variety of settings.

In essence, canning is not just a packaging choice; it’s a commitment to delivering the highest quality and most authentic tasting craft beverages to consumers.

What are the environmental benefits of choosing cans over bottles for craft beverages?

Choosing cans over bottles for craft beverages offers several environmental advantages:

- Recyclability: Aluminum cans are among the most recycled containers globally. They can be recycled indefinitely without losing quality or purity. This means that every time a can is recycled, it reduces the need for raw materials and the energy required to produce new cans.

- Energy Savings: The recycling process for aluminum cans uses up to 95% less energy than producing new aluminum from raw materials. This significant energy saving translates to reduced carbon emissions.

- Lightweight: Cans are lighter than glass bottles, which means transporting them requires less energy. This results in lower fuel consumption and fewer greenhouse gas emissions during transportation.

- Reduced Waste: Due to their durability, cans have a lower chance of breaking compared to glass bottles. This reduces waste from broken containers and the energy and resources needed to replace them.

- Space Efficiency: Cans are compact and stackable, allowing for more efficient storage and transportation. This means fewer trips are needed to transport the same amount of beverage, further reducing the carbon footprint.

- Safety: In areas where broken glass could pose a risk, like beaches or outdoor events, cans are a safer alternative. This reduces the environmental impact of cleaning up and disposing of broken glass.

In summary, while both cans and bottles have their merits, from an environmental perspective, cans offer several advantages that make them a more sustainable choice for packaging craft beverages like beer, kombucha, wine, and cider.

How can investing in a modern canning line improve the profitability of a craft beverage business?

Investing in a modern canning line can significantly enhance the profitability of a craft beverage business in several ways:

- Efficiency: Modern canning lines are designed for speed and precision. They can process large volumes of beverages in a short time, reducing labor costs and increasing production capacity.

- Quality Control: Advanced canning machines come with built-in quality checks, ensuring each can is filled accurately and sealed perfectly. This reduces wastage from overfills or compromised seals and ensures a consistent product for consumers.

- Reduced Spoilage: Proper canning preserves the freshness of the beverage, reducing the chances of spoilage or returns due to quality issues. This means fewer losses and higher customer satisfaction.

- Market Reach: Cans are lightweight and durable, making them easier and more cost-effective to distribute. This allows businesses to expand their market reach, accessing new customers in distant locations without significant shipping costs.

- Sustainability Appeal: With the growing consumer emphasis on sustainability, offering beverages in recyclable cans can be a unique selling point, attracting environmentally-conscious customers.

- Flexibility: Modern canning lines can often be adjusted to handle different can sizes or types, allowing businesses to offer a range of products without significant additional investment.

- Brand Visibility: Cans offer a larger surface area for branding compared to bottle labels. This provides an opportunity for more impactful branding and marketing, making the product stand out on shelves.

In essence, while the initial investment in a modern canning machine might be significant, the long-term benefits in terms of efficiency, quality, and market reach can lead to substantial profitability gains for a craft beverage business.

How does the canning process ensure the safety and hygiene of craft beverages like kombucha and cider?

The canning process is meticulously designed to prioritize the safety and hygiene of beverages, making it ideal for craft drinks like kombucha and cider. Here’s how:

- Hermetic Sealing: Once the beverage is in the can, it’s sealed hermetically. This airtight seal ensures that no external contaminants, including bacteria or other pathogens, can enter the can, preserving the beverage’s integrity.

- Protection from Light and Oxygen: Cans block out all light and oxygen, two factors that can degrade the quality of beverages and potentially promote the growth of unwanted microorganisms. This is especially crucial for drinks like kombucha, which are sensitive to light and oxygen exposure.

- Sanitization: Before filling, cans are typically sanitized using heat or chemical processes to ensure they are free from any potential contaminants.

- Pasteurization: Some craft beverages undergo a pasteurization process after canning. This involves briefly heating the sealed can to kill any remaining microorganisms, ensuring the beverage’s safety and extending its shelf life.

- Quality Checks: Modern canning lines often incorporate quality check systems that detect and reject cans that aren’t sealed correctly, ensuring that only perfectly sealed cans reach consumers.

- Reduced Human Contact: Automated canning lines minimize human contact with the beverage, reducing the risk of contamination.

- Durable Packaging: Aluminum cans are robust and less likely to break compared to glass bottles. This reduces the risk of external contaminants entering the beverage due to damaged packaging.

In summary, the canning process, combined with the inherent properties of aluminum cans, provides a safe and hygienic environment for craft beverages, ensuring that consumers receive a product of the highest quality and safety standards.

Why is it essential for craft beverage producers to consider the scalability of their canning lines?

Scalability in canning lines is a critical consideration for craft beverage producers for several reasons:

- Growth Potential: As a craft beverage brand gains popularity, the demand for its products will inevitably increase. A scalable canning line ensures that the producer can meet this growing demand without significant disruptions or the need for a complete system overhaul.

- Cost Efficiency: Investing in a scalable canning machine might have a higher initial cost, but it can be more cost-effective in the long run. It eliminates the need for frequent upgrades or the purchase of entirely new equipment as production needs grow.

- Adaptability: Scalable canning lines often come with modular components. This means that as the production requirements change, specific modules can be added or replaced without affecting the entire system. This adaptability is crucial for responding to market trends or introducing new products.

- Consistent Quality: Maintaining consistent product quality is vital for brand reputation. A scalable canning line ensures that even as production volumes increase, the quality of the canning process remains consistent, ensuring that every can meets the brand’s standards.

- Operational Efficiency: A scalable system can handle increased production volumes without significantly increasing operational times. This means that even as demand grows, the production turnaround remains efficient.

- Future-Proofing: The beverage industry is dynamic, with evolving consumer preferences and market trends. A scalable canning line provides the flexibility to adapt to these changes, ensuring the producer remains competitive.

- Resource Management: As production volumes increase, resource management becomes crucial. Scalable canning lines often come with integrated systems that optimize resource usage, reducing waste and ensuring efficient operations.

In essence, considering scalability when investing in a canning line is not just about preparing for growth. It’s about ensuring operational efficiency, cost management, and consistent product quality, all of which are crucial for the long-term success of a craft beverage producer.

How can craft beverage producers ensure that their canning process retains the authentic taste and quality of their product?

Retaining the authentic taste and quality of a craft beverage during the canning process is paramount for producers. Here’s how they can ensure this:

- Optimal Filling Techniques: Modern canning machines use techniques that minimize oxygen exposure during the filling process. Oxygen can alter the taste of beverages, so reducing its presence is crucial.

- Freshness Seals: Once filled, cans are immediately sealed to ensure freshness. This hermetic sealing prevents external contaminants and oxygen from entering, preserving the beverage’s original taste.

- Temperature Control: Maintaining the right temperature during the canning process is essential. Too much heat can alter the flavor profile of certain beverages. Producers often chill beverages before canning to ensure they remain at an optimal temperature.

- Quality Ingredients: The canning process can only retain the quality of what’s put into it. Using high-quality ingredients from the start ensures that the end product remains authentic in taste.<%2lFi>

- Sanitization: Ensuring that the cans and the canning environment are thoroughly sanitized prevents any foreign tastes or contaminants from affecting the beverage.

- Regular Quality Checks: Implementing regular quality checks and taste tests ensures that the product remains consistent across batches. Any deviations in taste can be quickly identified and addressed.

- Protective Linings: Many modern cans come with a protective lining that prevents the beverage from coming into direct contact with the metal. This ensures that there’s no metallic taste imparted to the drink.

- Limited Light Exposure: Cans naturally protect beverages from light exposure, which can degrade certain drinks, especially beers, altering their taste.

- Batch Testing: Before scaling up production, it’s wise to run a few batches through the canning process and conduct taste tests. This helps in fine-tuning the process to ensure optimal flavor retention.

- Continuous Training: Ensuring that the staff is well-trained and understands the importance of each step in the canning process is crucial. A well-informed team can identify potential issues before they affect product quality.

In essence, while the canning process involves several technical steps, the key to retaining the authentic taste and quality of a craft beverage lies in attention to detail, using quality ingredients, and regular monitoring.

How does the choice of canning machine impact the sustainability efforts of a craft beverage producer?

The choice of canning machine plays a pivotal role in the sustainability efforts of a craft beverage producer. Here’s how:

- Resource Efficiency: Modern canning machines are designed to be efficient in terms of water and energy usage. This not only reduces operational costs but also minimizes the environmental footprint of the production process.

- Waste Reduction: Advanced canning lines come with precision filling systems that reduce product wastage. They also have mechanisms to detect and reject defective cans, ensuring minimal waste.

- Recyclable Packaging: Aluminum cans are 100% recyclable and can be recycled indefinitely without loss of quality. By choosing a canning machine that supports the use of recyclable materials, producers contribute to a circular economy.

- Reduced Carbon Footprint: Cans are lightweight compared to glass bottles, which means reduced transportation emissions. Additionally, efficient canning machines have a lower energy consumption rate, further reducing the carbon footprint.

- Durability: Cans are robust and less prone to breakage compared to other packaging forms. This means fewer products are wasted due to packaging damage during transportation or handling.

- Compact Design: Some modern canning machines have a compact design, requiring less space for installation. This can lead to reduced energy consumption for heating, cooling, and lighting in production facilities.

- Longer Shelf Life: Proper canning extends the shelf life of beverages, reducing the chances of products going to waste before they reach the consumer.

- Support for Local Sourcing: Some canning machines are designed to handle smaller batches efficiently, allowing craft producers to work with local suppliers, reducing transportation emissions and supporting local economies.

- Maintenance and Upgrades: Machines that are easy to maintain and upgrade can have a longer operational life, reducing the need for frequent replacements and minimizing resource consumption.

- Consumer Perception: Consumers are becoming increasingly conscious of sustainability. By using a canning machine that supports sustainable practices, producers can appeal to this growing demographic, enhancing brand reputation.

In conclusion, the choice of canning machine is not just about operational efficiency and product quality. It’s also a reflection of a producer’s commitment to sustainability, which can have significant implications for the environment, brand perception, and long-term business success.

What are the primary benefits of using a canning machine for craft beverages like beer, kombucha, wine, and cider?

Canning machines have revolutionized the craft beverage industry, offering a myriad of benefits for producers of beer, kombucha, wine, and cider. Here are the primary advantages:

- Extended Shelf Life: Canning machines create an airtight seal, which prevents oxygen and contaminants from entering the can. This ensures that the beverage remains fresh for a more extended period, preserving its taste and quality.

- Portability: Cans are lightweight and robust, making them easy to transport. Whether it’s a picnic, a beach outing, or a hiking trip, consumers can conveniently carry their favorite craft beverage without the risk of breakage.

- Sustainability: Aluminum cans are 100% recyclable and can be repurposed indefinitely. This makes them an eco-friendly packaging option, aligning with the growing consumer demand for sustainable products.

- Protection from Light: Light can degrade certain beverages, especially beer, altering its taste. Cans naturally shield the contents from light exposure, ensuring consistent flavor.

- Efficient Production: Modern canning machines can fill and seal a large number of cans in a short time, enhancing production efficiency and meeting high demand.

- Cost-Effective: In the long run, canning can be more cost-effective than bottling. The lightweight nature of cans reduces transportation costs, and the durability minimizes losses due to breakage.

- Versatility: Canning machines can handle a variety of beverages, from carbonated drinks like beer and cider to still beverages like wine and kombucha. This versatility allows producers to diversify their product range using the same equipment.

- Branding Opportunities: The cylindrical shape of cans offers a larger surface area for branding compared to bottles. This provides producers with ample space to showcase their brand identity, tell their story, and engage consumers.

- Safety: Cans eliminate the risk of broken glass, making them a safer option for events, outdoor activities, and venues where glass might be prohibited.

- Consumer Preference: The modern consumer values convenience, sustainability, and quality. Canned craft beverages tick all these boxes, making them increasingly popular among a wide demographic.

In essence, the use of canning machines in the craft beverage industry is not just a trend but a reflection of evolving consumer preferences, production efficiencies, and a commitment to sustainability.

How does the canning process ensure the preservation of the unique flavors and aromas of craft beverages like kombucha, beer, and cider?

The canning process plays a pivotal role in preserving the unique flavors and aromas of craft beverages. Here’s how it ensures the integrity of drinks like kombucha, beer, and cider:

- Oxygen Elimination: Oxygen is a primary culprit in flavor degradation, especially in beers. Modern canning machines minimize oxygen exposure during the filling process, ensuring that the beverage’s taste remains unaltered.

- Hermetic Sealing: Once the beverage is in the can, it’s sealed immediately. This airtight seal prevents any external contaminants and oxygen from entering, preserving the beverage’s original aroma and taste.

- Protection from Light: Light, especially UV rays, can have a detrimental effect on beverages, causing what’s known as “skunky” off-flavors in beers. Cans act as a barrier to light, ensuring the drink inside remains unaffected.

- Temperature Stability: The canning process often involves chilling the beverage before sealing. This ensures that the drink remains at an optimal temperature, preserving its flavor profile.

- Material Integrity: Modern cans come with a protective lining that prevents the beverage from coming into direct contact with the metal. This ensures that there’s no metallic taste imparted to the drink, preserving its original flavor.

- Carbonation Retention: For carbonated drinks like beer and cider, maintaining the right level of carbonation is crucial for taste. The airtight seal of cans ensures that the carbonation is locked in, providing a consistent fizz with every sip.

- pH Stability: For beverages like kombucha, which undergo fermentation, maintaining a stable pH is essential. The sealed environment of a can ensures that the pH remains consistent, preserving the unique tangy flavor of kombucha.

- Consistency Across Batches: The automated nature of canning machines ensures that each can is filled and sealed under the same conditions. This consistency ensures that every can of beverage tastes as good as the last.

- Safety and Sanitization: The canning process involves rigorous sanitization steps. Clean cans and a sanitized environment ensure that no external contaminants affect the beverage’s flavor.

- Shelf Stability: Canned beverages don’t require refrigeration until they’re opened. This shelf stability ensures that the flavors remain intact even when stored at room temperature for extended periods.

In conclusion, the canning process is meticulously designed to preserve the unique flavors and aromas of craft beverages. From the moment the drink is poured into the can to the moment it’s opened by the consumer, every step ensures flavor preservation and a delightful drinking experience.

Why is canning considered a sustainable packaging option for craft beverages, and how does it compare to traditional bottling?

Canning has emerged as a sustainable packaging option for craft beverages, offering several environmental advantages over traditional bottling. Here’s a breakdown of its sustainability credentials:

- Recyclability: Aluminum cans are 100% recyclable and can be repurposed indefinitely without any degradation in quality. This means that every recycled can reduces the need for virgin aluminum, conserving energy and resources.

- Energy Efficiency: The recycling process for aluminum cans uses up to 95% less energy than producing new aluminum. This significant energy saving translates to reduced carbon emissions and a smaller environmental footprint.

- Reduced Waste: Due to their durability, cans have a lower risk of breakage compared to glass bottles. This means fewer products are wasted due to packaging damage during transportation or handling.

- Lightweight: Cans are much lighter than glass bottles. This weight difference results in reduced transportation emissions, as lighter loads require less fuel to transport.

- Compact Storage: Cans are stackable and take up less space than bottles, leading to more efficient storage and transportation. This compactness further reduces the carbon footprint associated with distribution.

- Protection from Light and Air: Cans provide a complete barrier against light and oxygen, two factors that can degrade beverages and reduce their shelf life. This protection means less wastage from spoiled products.

- Reduced Refrigeration Needs: Canned beverages cool down faster than bottled ones, reducing the energy required for refrigeration.

- Safety: Cans, being shatterproof, pose no risk of broken glass, making them a safer option for consumers and reducing waste from breakage.

- Consumer Engagement: The rise in consumer awareness about environmental issues means that many prefer sustainable packaging options. Cans cater to this demand, enhancing brand reputation and customer loyalty.

- Innovation in Design: Modern canning technology allows for innovations like resealable cans, further enhancing their sustainability profile by allowing consumers to portion their beverages and reduce wastage.

Compared to traditional bottling, canning offers a more sustainable, efficient, and consumer-friendly packaging solution. While glass bottles are also recyclable, the energy-intensive nature of glass production and recycling, combined with the weight and fragility of bottles, makes cans a more environmentally friendly choice for craft beverage packaging.

How do canning machines cater to the diverse needs of craft beverage producers, from kombucha to wine?

Canning machines have evolved to cater to the diverse needs of craft beverage producers, ensuring that each type of drink, from kombucha to wine, is packaged optimally. Here’s how these machines address the unique requirements of different beverages:

- Versatility in Volume: Modern canning machines can handle various can sizes, allowing producers to offer different volume options, from smaller cans for kombucha servings to larger ones for beers or ciders.

- Carbonation Control: Carbonation levels vary across beverages. While beers and ciders require a certain fizz, wines and kombuchas might have different carbonation needs. Canning machines can be adjusted to ensure the right carbonation level is maintained during the packaging process.

- Oxygen Purge: Oxygen can degrade the quality of beverages, especially wine. Advanced canning machines use a CO2 purge system to minimize oxygen exposure, preserving the drink’s aroma and flavor.

- Sanitization: Beverages like kombucha, which undergo fermentation, require stringent sanitization to prevent contamination. Canning machines come equipped with sanitization processes to ensure that cans are sterile before filling.

- Sealing Integrity: A perfect seal is crucial to prevent leaks and maintain the beverage’s quality. Canning machines are designed to ensure that each can is sealed flawlessly, regardless of the beverage inside.

- Fill Levels: Different beverages might have specific fill level requirements. For instance, wines might need a specific headspace to allow for expansion. Canning machines can be calibrated to ensure accurate fill levels for each beverage type.

- Speed and Efficiency: Craft beverage producers, especially those with limited batches, require efficient packaging solutions. Modern canning machines offer quick canning processes without compromising on quality, catering to the needs of small to medium-sized producers.

- Material Compatibility: Some beverages might react with certain can materials. Advanced cans come with protective linings to ensure that the drink doesn’t come into direct contact with the metal, preserving its original flavor.

- Temperature Control: Certain beverages, like wine, might need to be canned at specific temperatures to maintain their quality. Canning machines can be equipped with temperature control systems to cater to such requirements.

- Flexibility in Production: Modern canning machines are designed for flexibility, allowing producers to switch between different beverages easily. This adaptability is crucial for craft producers who might offer a diverse range of drinks.

In essence, canning machines have become an indispensable tool for craft beverage producers, offering tailored solutions for each drink type. From ensuring the right carbonation levels for beers to maintaining the delicate aromas of wines, these machines cater to every nuance of the craft beverage world.

What are the primary benefits of using a canning line for craft beverage producers, especially for those in the beer, kombucha, wine, and cider industries?

The adoption of canning lines by craft beverage producers has surged in recent years, and for good reason. Here are the primary benefits of using a canning machine, especially for those in the beer, kombucha, wine, and cider industries:

- Extended Shelf Life: Canning lines ensure a hermetic seal, keeping out oxygen and contaminants. This extends the shelf life of beverages, allowing producers to distribute their products over greater distances without compromising quality.

- Superior Product Protection: Cans provide a complete barrier against light and oxygen, two of the primary culprits that can degrade beverage quality. This is especially crucial for beers, which can develop off-flavors when exposed to light.

- Cost Efficiency: Over time, canning lines can be more cost-effective than other packaging methods. The lightweight nature of cans reduces transportation costs, and the efficiency of modern canning lines can lead to faster production times and lower labor costs.

- Eco-friendly: Aluminum cans are highly recyclable, often being turned into new cans within 60 days. This recyclability reduces the environmental footprint of the beverage industry.

- Versatility: Canning lines can accommodate various can sizes and types, allowing producers to offer a range of packaging options to consumers. Whether it’s a small can of kombucha or a larger can of cider, producers have flexibility in their offerings.

- Safety: Cans are shatterproof, reducing the risk of breakage during transportation and offering a safer option for outdoor events and venues where glass might be prohibited.

- Brand Visibility: The 360-degree canvas of a can offers ample space for branding and design, allowing producers to create eye-catching packaging that stands out on the shelves.

- Rapid Cooling: Cans cool down faster than bottles, meaning consumers can enjoy their beverage at the ideal temperature sooner.

- Space Efficiency: Cans are stackable and take up less space than bottles, leading to more efficient storage and transportation.

- Consumer Trends: With a shift in consumer perception, cans are no longer seen as inferior to bottles. Especially in the craft beer industry, cans are often preferred for their portability and ability to maintain product freshness.

In conclusion, canning lines offer a multitude of benefits for craft beverage producers, aligning with both operational needs and consumer preferences. As the beverage industry continues to evolve, canning lines provide a modern, efficient, and sustainable solution for packaging.

How does the canning process ensure the freshness and quality of beverages, particularly in the craft canning sector for products like beer, kombucha, wine, and cider?

The canning process plays a pivotal role in preserving the freshness and quality of beverages, especially in the craft canning sector. Here’s how the process ensures that products like beer, kombucha, wine, and cider retain their original taste and character:

- Oxygen Elimination: Oxygen is a major enemy of freshness in beverages. During the canning process, cans are often purged with CO2 before filling to eliminate any residual oxygen. This prevents oxidation, which can lead to off-flavors and spoilage.

- Light Protection: Light, especially UV rays, can degrade certain beverages, causing what’s known as “skunky” flavors in beers. Cans provide a complete barrier against light, ensuring that the product inside remains unaffected.

- Hermetic Seal: Once filled, cans are sealed hermetically, ensuring that no external contaminants or additional oxygen can enter. This seal maintains the beverage’s carbonation and prevents spoilage.

- Temperature Stability: Cans have excellent thermal conductivity, allowing beverages to cool down quickly and maintain a stable temperature. This rapid cooling is beneficial for beverages like beer, which are best enjoyed cold.

- Protection from Contaminants: The canning process is typically carried out in a controlled environment, ensuring that the product is free from external contaminants. This is especially crucial for products like kombucha, which can be sensitive to external microbes.

- pH Control: For beverages like wine and cider, maintaining the right pH is crucial for flavor and stability. The canning process ensures that these beverages are canned at the correct pH, preserving their taste and preventing unwanted fermentations.

- Consistency: Modern canning lines are equipped with sensors and quality control mechanisms that ensure each can is filled to the exact required level, maintaining consistency across the batch.

- Durability: Cans are robust and can withstand the rigors of transportation better than other packaging forms. This durability ensures that the beverage inside remains intact and fresh, even after long journeys.

- Eco-friendly Packaging: Aluminum cans are recyclable, and using them reduces the carbon footprint of the beverage. This environmental benefit indirectly contributes to the quality perception of the product by eco-conscious consumers.

- Consumer Perception: The rise in craft canning has shifted consumer perception. Many now associate cans with freshness, given the knowledge that cans protect against light and oxygen, two primary culprits of beverage degradation.

In essence, the canning process, combined with the inherent properties of cans, offers an optimal packaging solution for craft beverages. It ensures that the product reaching the consumer is as fresh and flavorful as it was when it left the brewery or production facility.

Why is craft canning becoming increasingly popular among small-scale beverage producers, especially those producing beer, kombucha, wine, and cider?

Craft canning has seen a significant surge in popularity among small-scale beverage producers in recent years. Here’s why this trend is gaining momentum, especially among those producing beer, kombucha, wine, and cider:

- Consumer Demand: The modern consumer is looking for portability and convenience. Cans are lightweight, easy to carry, and perfect for on-the-go consumption, making them a preferred choice for many.

- Sustainability: Aluminum cans are highly recyclable, often being turned back into new cans within a short period. This eco-friendliness appeals to environmentally conscious consumers and producers alike.

- Quality Preservation: As previously mentioned, cans offer superior protection against light and oxygen, two primary factors that can degrade beverage quality. This ensures that the product remains fresh from the production facility to the consumer’s hands.

- Economic Sense: For small-scale producers, investing in a canning line can be more cost-effective in the long run. The reduced shipping weight of cans (compared to bottles) can lead to significant savings in transportation costs.

- Brand Visibility: The cylindrical shape of a can provides a larger canvas for branding and design. This allows producers to create distinctive and eye-catching packaging that stands out on the shelves.

- Safety and Versatility: Cans are shatterproof, making them a safer option for venues where glass might be prohibited. Additionally, they are suitable for a variety of beverages, from carbonated beers to still wines.

- Consumer Perception Shift: Once associated primarily with mass-produced beverages, cans are now embraced by the craft industry. This shift in perception means that consumers are more open to trying craft products in cans, associating them with quality and innovation.

- Space Efficiency: Cans are stackable and take up less storage space than bottles, leading to more efficient storage both in retail settings and during transportation.

- Rapid Market Response: With the ability to produce smaller batches, craft producers can quickly respond to market trends, releasing limited-edition or seasonal beverages in cans.

- Innovation and Experimentation: The craft beverage industry thrives on innovation. Cans offer an opportunity for producers to experiment with different sizes, designs, and even interactive elements (like thermochromic inks that change color with temperature).

In conclusion, the rise of craft canning is a confluence of consumer demand, economic factors, and the inherent benefits of cans as a packaging medium. As the beverage industry continues to evolve, it’s clear that cans will play a pivotal role in shaping its future.

How do canning machines and canning lines enhance the efficiency and scalability of beverage production, especially for craft beverages like beer, kombucha, wine, and cider?

Canning machines and canning lines have revolutionized the beverage industry, particularly in the craft segment. Here’s how they enhance efficiency and scalability for producers of beer, kombucha, wine, and cider:

- Speed and Volume: Modern canning lines can process thousands of cans per hour. This speed allows producers to meet demand efficiently, especially during peak seasons or when launching new products.

- Consistency: Automated canning lines ensure that each can is filled, sealed, and labeled consistently. This uniformity is crucial for maintaining brand reputation and product quality.

- Flexibility: Many canning lines are modular, allowing producers to scale up or adapt to different can sizes and types as their needs evolve.

- Waste Reduction: Precision filling mechanisms minimize product wastage. Overflows and underfills are significantly reduced, ensuring optimal product volume in each can.

- Quality Control: Advanced sensors and quality checks are integrated into many canning lines. These systems detect and reject defective cans, ensuring that only the best products reach consumers.

- Oxygen Reduction: As mentioned earlier, oxygen is detrimental to many beverages. Modern canning machines are designed to minimize oxygen pickup during the filling process, preserving the freshness of the product.

- Space Efficiency: Compact canning lines are available for smaller production facilities, ensuring that even craft producers with limited space can benefit from automated canning.

- Cost Savings: While the initial investment in a canning line can be significant, the long-term savings in labor, waste reduction, and increased production capacity often justify the expense.

- Safety: Automated canning lines reduce the need for manual handling, decreasing the risk of workplace injuries. They also ensure that cans are sealed securely, preventing potential contamination.

- Market Reach: With the ability to produce larger batches efficiently, craft producers can expand their market reach, distributing their products to a wider audience and even exploring export opportunities.

In essence, canning machines and lines are not just about packaging; they’re about empowering producers to optimize their operations, maintain product quality, and meet the ever-evolving demands of the beverage market. As the craft beverage industry continues to grow, the role of efficient and scalable canning machines becomes even more critical.

What are the environmental benefits of using canning machines for packaging beverages, especially in the realm of craft beverages like beer, kombucha, wine, and cider?

The environmental impact of packaging choices is a growing concern for both producers and consumers. Canning machines, when used for packaging beverages, offer several environmental benefits, especially for craft beverages. Here’s a breakdown of these benefits:

- Recyclability: Aluminum cans are among the most recyclable packaging materials. They can be recycled indefinitely without losing quality, reducing the need for raw materials and the energy required to produce new cans.

- Energy Savings: Recycling aluminum cans saves up to 95% of the energy required to produce the same amount of aluminum from raw materials. This significant energy saving translates to reduced greenhouse gas emissions.

- Reduced Carbon Footprint: Cans are lightweight, which means transporting them requires less energy compared to heavier packaging options. This results in lower carbon emissions during transportation.

- Waste Reduction: Modern canning machines are designed for precision, ensuring minimal wastage during the filling process. This efficiency reduces product waste and the environmental impact associated with it.

- Less Water Usage: The recycling process for aluminum cans uses less water compared to producing new aluminum. This conservation is crucial, especially in regions where water scarcity is a concern.

- Durability: Cans are robust and less prone to breakage compared to glass bottles. This durability reduces the waste associated with broken or damaged packaging.

- Space Efficiency: Cans are stackable and compact, allowing for more efficient storage and transportation. This efficiency translates to fewer trips and, consequently, reduced fuel consumption and emissions.

- Reduced Landfill Waste: As cans are highly recyclable, they are less likely to end up in landfills. Even if they do, they degrade faster than many other packaging materials.

- Consumer Awareness: The rise of craft beverages has brought with it a more informed and environmentally conscious consumer base. By choosing cans, producers align with the values of these consumers, promoting sustainability and responsible consumption.

- Local Sourcing: Many craft beverage producers prioritize sourcing their materials, including packaging, locally. Using locally produced cans reduces the environmental impact associated with long-distance transportation.

In conclusion, the choice of using canning machines for packaging craft beverages is not just an economic or quality-driven decision; it’s an environmentally responsible one. As the global community becomes more aware of the need for sustainable practices, the role of eco-friendly packaging solutions like cans becomes even more vital.

How does the canning process ensure the freshness and quality of beverages, particularly for craft products like beer, kombucha, wine, and cider?

Ensuring the freshness and quality of beverages is paramount, especially in the craft industry where the taste, aroma, and overall experience are central to the product’s appeal. The canning process plays a pivotal role in preserving these attributes. Here’s how:

- Protection from Light: Light, especially UV rays, can degrade certain compounds in beverages, leading to off-flavors. Aluminum cans block out all light, ensuring the product inside remains unaffected.

- Airtight Sealing: Cans are hermetically sealed, preventing any air from entering. This is crucial as oxygen can oxidize beverages, altering their taste and reducing their shelf life.

- Consistent Carbonation: For carbonated beverages like beer and cider, maintaining consistent carbonation levels is essential for the desired mouthfeel. The airtight seal of cans ensures that the carbonation level remains consistent from the time of packaging until consumption.

- Temperature Stability: Cans cool down faster than other packaging materials. This rapid cooling is beneficial for beverages that are best enjoyed chilled, ensuring a refreshing experience for the consumer.

- Material Integrity: Unlike some plastics, aluminum doesn’t leach any flavors into the beverage. This ensures that the taste of the product remains as the producer intended.

- Reduced Contamination Risk: The automated canning process, especially in modern canning lines, minimizes human contact with the product. This reduces the risk of contamination, ensuring a safer product for the consumer.

- Portability: The robustness and lightweight nature of cans make them ideal for transport. This means that the product can reach consumers in remote locations without compromising on freshness.

- Extended Shelf Life: The combined benefits of light protection, airtight sealing, and reduced contamination risk mean that beverages in cans often have a longer shelf life compared to other packaging methods.

- Quality Checks: Modern canning lines often come equipped with sensors and quality checks that ensure each can is filled and sealed to the highest standards. Any defects are quickly identified and rectified.

- Consumer Perception: The rise in popularity of craft beverages in cans has shifted consumer perception. Many now associate cans with quality and freshness, especially when they understand the benefits of canning.

In essence, the canning process is not just about convenience or aesthetics; it’s a carefully designed method to ensure that every sip taken by the consumer is as fresh and flavorful as the producer intended. As the craft beverage industry continues to innovate, the role of canning in ensuring product quality becomes even more pronounced.

How can integrating a canning line into my production process elevate the branding and market presence of my craft beverage, be it beer, kombucha, wine, or cider?

Integrating a canning line into your production process can significantly enhance your craft beverage’s branding and market presence. Here’s how:

- Packaging Design Flexibility: Cans offer a broad canvas for creative and eye-catching designs. This allows brands to stand out on the shelves and resonate with their target audience.

- Eco-friendly Branding: As consumers become more environmentally conscious, using recyclable aluminum cans can position your brand as eco-friendly, appealing to a growing segment of the market.

- Portability and Convenience: Cans are lightweight and easy to transport, making them perfect for events, picnics, and other outdoor activities. This can expand your product’s reach to various settings, enhancing brand visibility.

- Freshness Guarantee: As cans preserve the freshness of beverages, consumers will associate your brand with consistent quality and taste, building trust and loyalty.

- Innovation Perception: Adopting canning lines, especially for products traditionally not canned (like certain wines or kombuchas), can position your brand as innovative and forward-thinking.

- Market Expansion: Cans, being robust and lightweight, are ideal for expanding into new markets, even internationally. This can boost your brand’s presence in regions previously untapped.

- Collaborations and Limited Editions: The flexibility of canning allows for limited runs, perfect for collaborations with other brands or special edition releases, creating buzz and excitement around your brand.

- Safety and Integrity: Cans reduce the risk of breakage compared to glass, ensuring that your product reaches the consumer in perfect condition, reinforcing a perception of quality.

- Cost Efficiency: Over time, canning can be more cost-effective than other packaging methods, allowing for competitive pricing or increased investment in branding and marketing efforts.

- Trend Alignment: With many craft producers shifting to cans, being part of this trend can position your brand as current and in touch with industry shifts.

Incorporating a canning line isn’t just a production decision; it’s a strategic move that can redefine your brand’s narrative, appeal, and market positioning. As the craft beverage landscape becomes more competitive, such decisions can be pivotal in carving out a distinct and memorable brand identity.

How does the investment in a modern canning line impact the overall production efficiency and scalability for craft beverages like beer, kombucha, wine, and cider?

Investing in a modern canning line can have profound effects on the production efficiency and scalability of craft beverages. Here’s a breakdown of the benefits:

- Increased Production Speed: Modern canning lines are designed for high-speed operations, allowing for faster packaging and increased output, meeting growing demand more effectively.

- Reduced Waste: Precision filling and sealing mechanisms minimize product wastage, ensuring that every drop of your craft beverage is utilized efficiently.

- Quality Assurance: Advanced sensors and quality checks in modern canning lines ensure that each can is filled and sealed to the highest standards, reducing the chances of defects and ensuring consistent product quality.

- Scalability: As your brand grows, a modern canning line can handle increased production volumes without significant changes or upgrades, providing a clear path to scale operations.

- Energy Efficiency: Many contemporary canning lines are designed with energy conservation in mind, reducing operational costs and aligning with sustainable business practices.

- Space Optimization: Modern canning equipment is often more compact and designed for optimal space utilization, allowing for efficient layout planning and potentially reducing facility costs.

- Flexibility: Some advanced canning lines can handle various can sizes and types, allowing brands to diversify their product offerings without needing separate equipment.

- Safety Enhancements: Modern lines come with enhanced safety features, ensuring a safer working environment for employees and reducing the risk of workplace accidents.

- Reduced Labor Costs: Automation features in contemporary canning lines can reduce the need for manual labor, leading to cost savings in the long run.

- Consistent Branding: Uniform filling and sealing ensure that every product is consistent, reinforcing brand reliability and trust among consumers.

In essence, the investment in a modern canning line is not just about increasing production capacity; it’s about enhancing overall operational efficiency, ensuring product quality, and providing a foundation for future growth. For craft beverage producers, this can be the difference between being a local favorite and becoming a recognized brand on a larger scale.

What are the potential cost savings and ROI when transitioning from traditional packaging methods to a dedicated canning line for craft beverages such as beer, kombucha, wine, and cider?

Transitioning to a dedicated canning line from traditional packaging methods can offer significant cost savings and a favorable return on investment (ROI) for craft beverage producers. Here’s a breakdown of the financial benefits:

- Material Costs: Aluminum cans can be more cost-effective than glass bottles, especially when purchased in bulk. Over time, this can result in substantial savings on packaging materials.

- Reduced Waste: Modern canning lines are precise, leading to minimal product wastage during the filling process. This ensures that you get the most out of every batch produced.

- Energy Efficiency: Canning lines, especially newer models, are designed for energy efficiency, leading to reduced energy bills over time.

- Labor Savings: Automated canning processes reduce the need for manual labor, leading to potential savings on labor costs.

- Transportation Costs: Cans are lighter and more compact than glass bottles, leading to reduced shipping and transportation costs. Additionally, the reduced risk of breakage means fewer returns and replacements.

- Storage Efficiency: Cans are stackable and require less storage space than bottles, potentially reducing warehouse and storage costs.

- Increased Production Capacity: Faster packaging speeds mean more products can be produced and sold in the same timeframe, leading to increased revenues.

- Brand Expansion: The portability and durability of cans open up new markets and distribution channels, potentially increasing sales and brand reach.

- Reduced Breakage: The sturdy nature of cans means fewer losses due to breakage compared to glass bottles, leading to more products reaching the end consumer.

- Sustainability and Brand Image: As consumers become more eco-conscious, using recyclable cans can enhance brand image, potentially leading to increased sales and customer loyalty.

While there’s an initial investment involved in setting up a canning line, the long-term cost savings, increased production capacity, and potential for brand expansion can result in a favorable ROI. It’s essential to conduct a detailed cost-benefit analysis, considering both immediate and future needs, to determine the potential ROI for your specific operation.